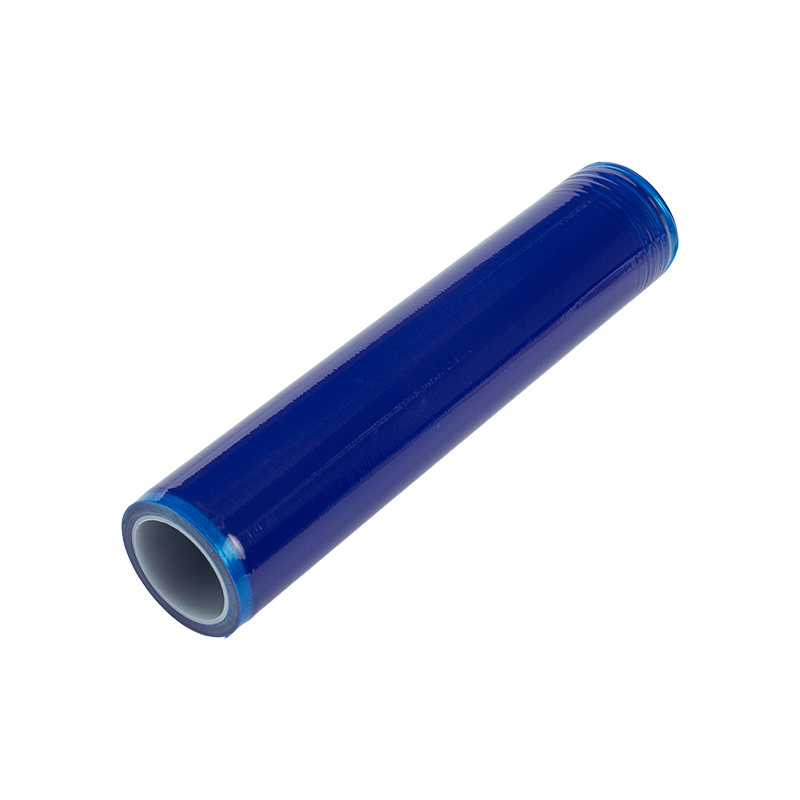

Cleanroom dust-free wiper roll are specialized cleaning products designed for use in controlled environments like cleanrooms. They are typically made from low-lint and low-particulate materials and are used to clean, wipe, and maintain the cleanliness of surfaces, equipment, and products within cleanrooms. Here's a more detailed explanation of cleanroom dust-free wiper rolls and their applications:

Characteristics of Cleanroom Dust-Free Wiper Rolls:

Low Particle Generation: These wiper rolls are engineered to minimize the release of particles and lint during use, making them suitable for environments where even tiny contaminants can be a concern.

High Absorbency: Cleanroom wiper rolls are often designed to be highly absorbent, allowing them to effectively capture and hold liquids, chemicals, and particles.

Material Selection: They are typically made from materials such as microfiber, polyester, or polypropylene, or a combination of these materials, which are chosen for their cleanliness and durability.

Variety of Sizes: Cleanroom wiper rolls come in various widths and lengths, providing flexibility to meet specific cleaning needs in cleanroom settings.

Applications in Cleanroom Environments:

Surface Cleaning: Cleanroom wiper rolls are used to clean and wipe surfaces such as countertops, workbenches, equipment, and cleanroom walls to maintain a clean and particle-free environment.

Spill Cleanup: They are employed to quickly and efficiently clean up spills of liquids or chemicals within the cleanroom without leaving residues or contaminants.

Equipment Maintenance: Cleanroom wiper rolls are used for routine maintenance and cleaning of sensitive equipment and machinery to prevent particle contamination and ensure optimal performance.

Product Cleaning: In industries like semiconductor manufacturing and pharmaceuticals, these wiper rolls are used to clean and wipe down sensitive products and components to ensure their cleanliness and quality.

Gowning and Gloving: Some cleanroom wiper rolls may also be used during the gowning and gloving process to remove particles and ensure the cleanliness of personnel entering the cleanroom.

Sterile Environments: In pharmaceutical and biotechnology cleanrooms, sterile cleanroom wiper rolls may be used to maintain aseptic conditions and minimize the risk of microbial contamination.

Electronics Manufacturing: In electronic manufacturing cleanrooms, these wiper rolls are employed to remove dust and particles from delicate electronic components to prevent defects and ensure product quality.

ESD Control: Cleanroom wiper rolls may be designed to control electrostatic discharge (ESD) in environments where sensitive electronic devices are manufactured or assembled.

Cleanroom dust-free wiper rolls play a critical role in maintaining the cleanliness, quality, and controlled conditions required in various industries such as semiconductor manufacturing, biotechnology, pharmaceuticals, aerospace, and electronics. They are an essential tool for contamination control and ensuring that cleanroom environments meet stringent standards.

+86-13328056777

+86-13328056777

英语

英语 西班牙语

西班牙语 俄语

俄语 Cleanroom Dust-free Wiper

Cleanroom Dust-free Wiper Cleanroom Dust-free Wiper Roll

Cleanroom Dust-free Wiper Roll Cleanroom Dust Free Paper

Cleanroom Dust Free Paper Cleanroom Dust Free Paper roll

Cleanroom Dust Free Paper roll Cleanroom Anti-static Clothing

Cleanroom Anti-static Clothing Cleanroom Anti-static shoes

Cleanroom Anti-static shoes Cleanroom Sticky

Cleanroom Sticky Dust-free Cleaning Sticks/Swabs

Dust-free Cleaning Sticks/Swabs