Cleanroom dust-free wiper are specifically designed and manufactured for use in controlled environments like cleanrooms, where maintaining a high level of cleanliness and preventing contamination is critical. They differ from regular paper towels or cleaning cloths in several ways:

Material Selection: Cleanroom wipers are made from materials that are low in lint and particulate generation. Common materials include microfiber, polyester, polypropylene, or blends of these materials. Regular paper towels and cleaning cloths are often made from materials that shed more lint and particles.

Low Particle Release: Cleanroom wipers are engineered to minimize particle release during use. They are specially treated or processed to reduce the risk of contaminating sensitive surfaces. In contrast, standard paper towels and cleaning cloths may release more lint and particles, which can be problematic in cleanroom environments.

Sterility and Purity: In some cleanroom applications, wipers need to be sterilized and packaged in a way that maintains their cleanliness. This is not typically a requirement for regular paper towels or cleaning cloths.

Size and Shape: Cleanroom wipers come in various sizes and shapes to meet the specific needs of cleanroom operators. They can be designed to fit into cleanroom wipes dispensers or containers, allowing for controlled and contamination-free access.

Absorbency and Chemical Compatibility: Cleanroom wipers are often engineered to be highly absorbent and compatible with various cleaning agents and disinfectants commonly used in cleanroom settings. Regular paper towels or cleaning cloths may not have these specific properties.

Strict Quality Control: Manufacturers of cleanroom wipers adhere to strict quality control standards to ensure that their products meet the cleanliness and particle generation requirements of cleanroom classifications. Regular paper towels and cleaning cloths may not undergo such rigorous quality control measures.

Cost: Cleanroom wipers are typically more expensive than regular paper towels or cleaning cloths due to the specialized materials and manufacturing processes used.

Environmental Considerations: Cleanroom wipers are often designed for single-use and disposal to minimize the risk of cross-contamination. In contrast, regular paper towels and cleaning cloths may be reusable and have different environmental considerations.

Cleanroom dust-free wipers are engineered and manufactured with a focus on minimizing particle release and maintaining a controlled, clean environment, making them essential tools in industries such as semiconductor manufacturing, pharmaceuticals, biotechnology, aerospace, and more. Regular paper towels and cleaning cloths are generally not suitable for these critical applications due to their higher propensity to generate lint and particles.

+86-13328056777

+86-13328056777

英语

英语 西班牙语

西班牙语 俄语

俄语 Cleanroom Dust-free Wiper

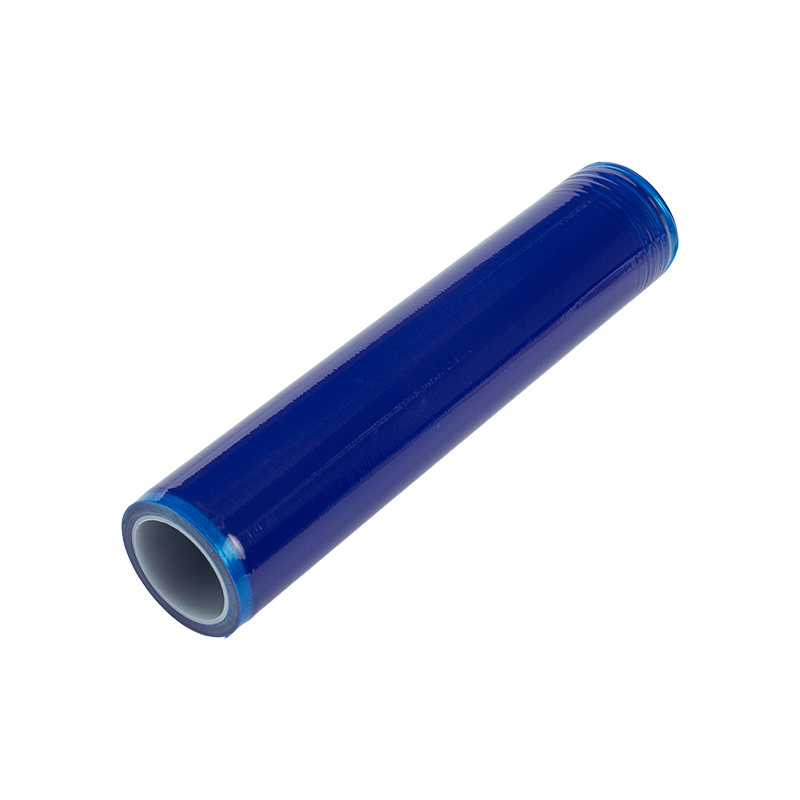

Cleanroom Dust-free Wiper Cleanroom Dust-free Wiper Roll

Cleanroom Dust-free Wiper Roll Cleanroom Dust Free Paper

Cleanroom Dust Free Paper Cleanroom Dust Free Paper roll

Cleanroom Dust Free Paper roll Cleanroom Anti-static Clothing

Cleanroom Anti-static Clothing Cleanroom Anti-static shoes

Cleanroom Anti-static shoes Cleanroom Sticky

Cleanroom Sticky Dust-free Cleaning Sticks/Swabs

Dust-free Cleaning Sticks/Swabs