Industry Knowledge

How do cleanroom sticky mats and rollers contribute to preventing cross-contamination between different cleanroom areas and maintaining controlled conditions throughout a facility?

Cleanroom sticky mats and rollers play a vital role in preventing cross-contamination between different cleanroom areas and maintaining controlled conditions throughout a facility. Here's how they contribute to these essential functions:

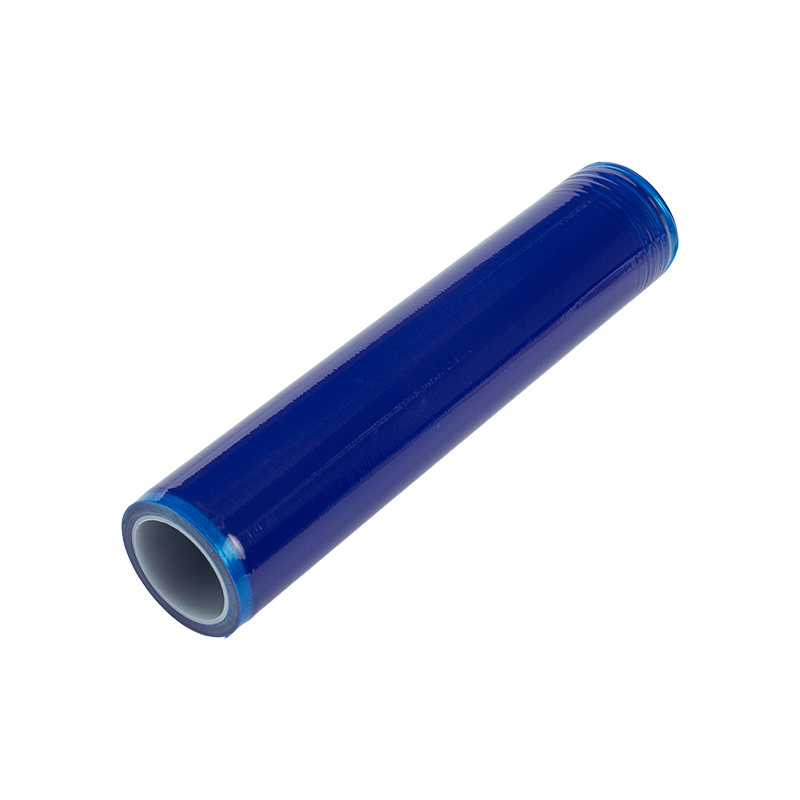

Particle and Contaminant Removal: Sticky mats and rollers are designed with adhesive sheets that effectively capture and retain particles, dust, fibers, and contaminants present on the soles of shoes, wheels of equipment, or other surfaces. As personnel or equipment pass over these adhesive surfaces, contaminants are removed, reducing the risk of them being transported from one area to another.

Contamination Source Control: By placing sticky mats or using sticky rollers at key entry and exit points of cleanrooms or between different cleanroom areas, operators prevent external contaminants from entering or being spread within the controlled environment. This source control helps maintain the cleanliness and integrity of each cleanroom space.

Gowning Room Transition: Sticky mats are often placed in gowning rooms or anterooms as a transitional step before personnel enter the main cleanroom. This ensures that contaminants, including lint and particles from regular clothing, are removed from footwear before donning cleanroom garments, reducing the introduction of external contaminants.

Equipment and Material Transfer: Sticky rollers can be used to clean wheels and casters on equipment or carts used to transport materials and products within the cleanroom. This prevents particles and contaminants from adhering to wheels and potentially being deposited in other cleanroom areas.

Maintaining Cleanroom Classification: Cleanrooms are classified based on the maximum allowable particle counts per cubic meter of air. The use of sticky mats and rollers helps ensure that particle counts remain within the defined limits for each cleanroom class, helping to maintain the cleanroom's classification and controlled conditions.

Minimizing Foot Traffic Contamination: Sticky mats placed near entry points minimize foot traffic contamination. Cleanroom personnel and visitors step on the mats, removing contaminants from their footwear, which would otherwise be spread throughout the cleanroom.

Regular Maintenance: Regular replacement or re-rolling of adhesive sheets on sticky rollers and mats ensures their continued effectiveness. This maintenance prevents saturation and loss of adhesive properties, maintaining their ability to capture contaminants.

Visual Confirmation: The adhesive surfaces of sticky mats and rollers are often colored to provide a visual indication of their condition. When they become dirty or reach the end of their usable life, the color change alerts operators that replacement or maintenance is needed.

Cost-Effective Contamination Control: Sticky mats and rollers offer a cost-effective and practical solution for contamination control compared to more complex and expensive systems. They require minimal training and are easy to implement.

Cleanroom sticky mats and rollers are integral tools for contamination control in cleanroom environments. They serve as the first line of defense in preventing cross-contamination between different cleanroom areas, ensuring that controlled conditions are maintained throughout the facility and supporting the cleanliness and integrity of the cleanroom classification.

+86-13328056777

+86-13328056777

英语

英语 西班牙语

西班牙语 俄语

俄语 Cleanroom Dust-free Wiper

Cleanroom Dust-free Wiper Cleanroom Dust-free Wiper Roll

Cleanroom Dust-free Wiper Roll Cleanroom Dust Free Paper

Cleanroom Dust Free Paper Cleanroom Dust Free Paper roll

Cleanroom Dust Free Paper roll Cleanroom Anti-static Clothing

Cleanroom Anti-static Clothing Cleanroom Anti-static shoes

Cleanroom Anti-static shoes Cleanroom Sticky

Cleanroom Sticky Dust-free Cleaning Sticks/Swabs

Dust-free Cleaning Sticks/Swabs